Extraction Conceptualization

Designing botanical extraction equipment is a fascinating journey. We can pull ideas and concepts from other industries, but nothing extracts the same as cannabis. Our equipment is from unchartered territory. Most of the time we come up with a dozen concepts to achieve a particular goal. Turning those concepts into reality takes many considerations; sometimes the concept is just not buildable; sometimes it doesn’t make financial sense (too expensive). The best concepts are both simple and elegant. Many times the concept starts out simple, becomes increasingly complex, then is refined into a streamlined product that’s also buildable. Having not known the process to reach the end, it would be easy to see the result and claim it is obvious.

Thomas Edison said “Genius is one percent inspiration and ninety nine percent perspiration.”

Our best concepts come from having a wide variety of people in the room throwing out ideas. An engineer, a fabricator, a chemist, an artist, a financial officer, and a psychologist make for a well rounded background to pull from. Ideas sometimes come from the most unsuspecting places, and everyone has a voice in the room. Everyone on our team is encouraged to voice their ideas. Sometimes the cloud of physics and reality gets in the way of a beautiful vision.

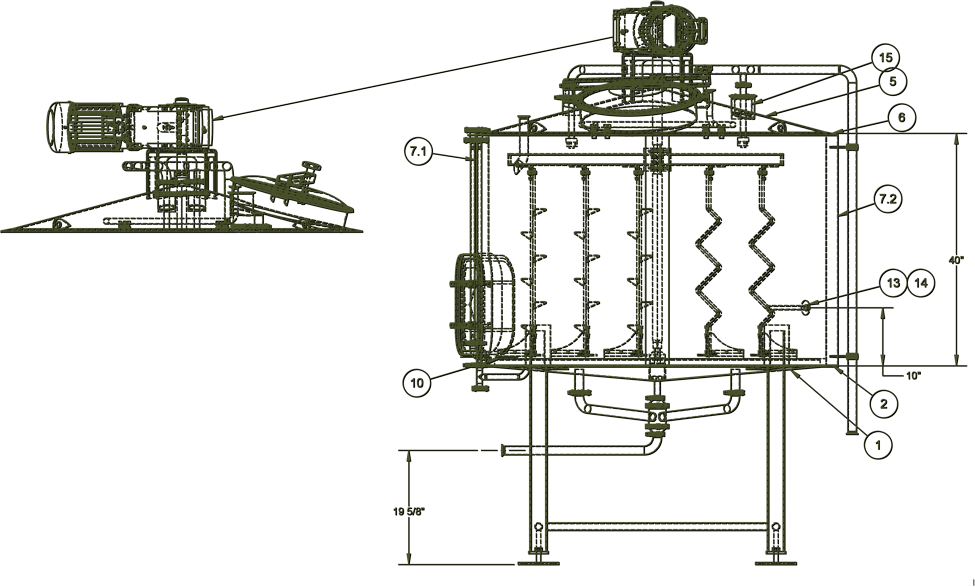

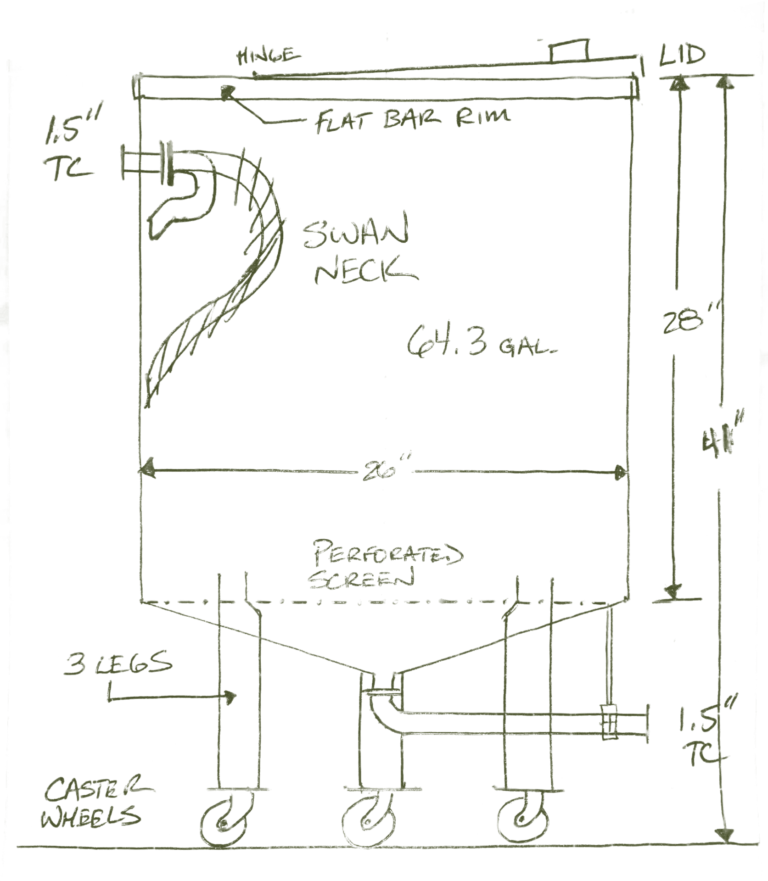

When we started building extraction equipment, we based our concepts on what we knew; Craft Beer. In a large sense, extracting wort from barley is not altogether different than extracting oil from Hemp. We use the same stainless steel building materials, there’s heat and chilling, vacuum and pressure. Without a standard extraction market and not knowing the equipment size and throughput scale, we sized our initial extraction equipment similar to craft brewing equipment, which happened to be many times bigger than what most of our competitors were building. Our first extractor could extract 500lbs of hemp at a time when products on the market aimed for 20-30lbs at a time.

Fermentation Conceptualization

Our customers are the best feedstock for fermentation concepts. Sure there’s innovation happening with fermentation, but other than a short period of prohibition, humans have been fermenting stuff for thousands of years. Advancements are incremental. But it’s those small improvements that drive Craft Beer Brewing into areas it’s never been before. We don’t have a brewery on site, but many of us have worked in breweries in the past. Still, the best ideas don’t come from theoretical simulations, but from boots on the brewery floor.

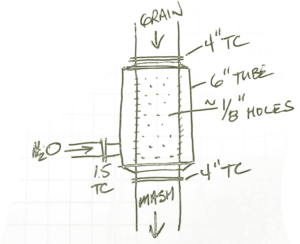

Back in 2015 we developed a “super fancy” mash tun hydrator with a tube sight glass, coned turbulence inducers, and dual water injection vortices. We built and supplied 4-5 breweries with this innovation as eye-candy for their brewhouses. The brewers started reporting clogs, ineffective hydration, and it turns out the hydrator didn’t work. We quickly made a simple hydrator as a stand-in for the “super fancy” while we had our customers ship them back so we could make improvements. The quick prototype “stand-in” worked so well all our brewers who had the super fancy hydrator preferred the stand-in.

Testing is paramount, and KISS rules.