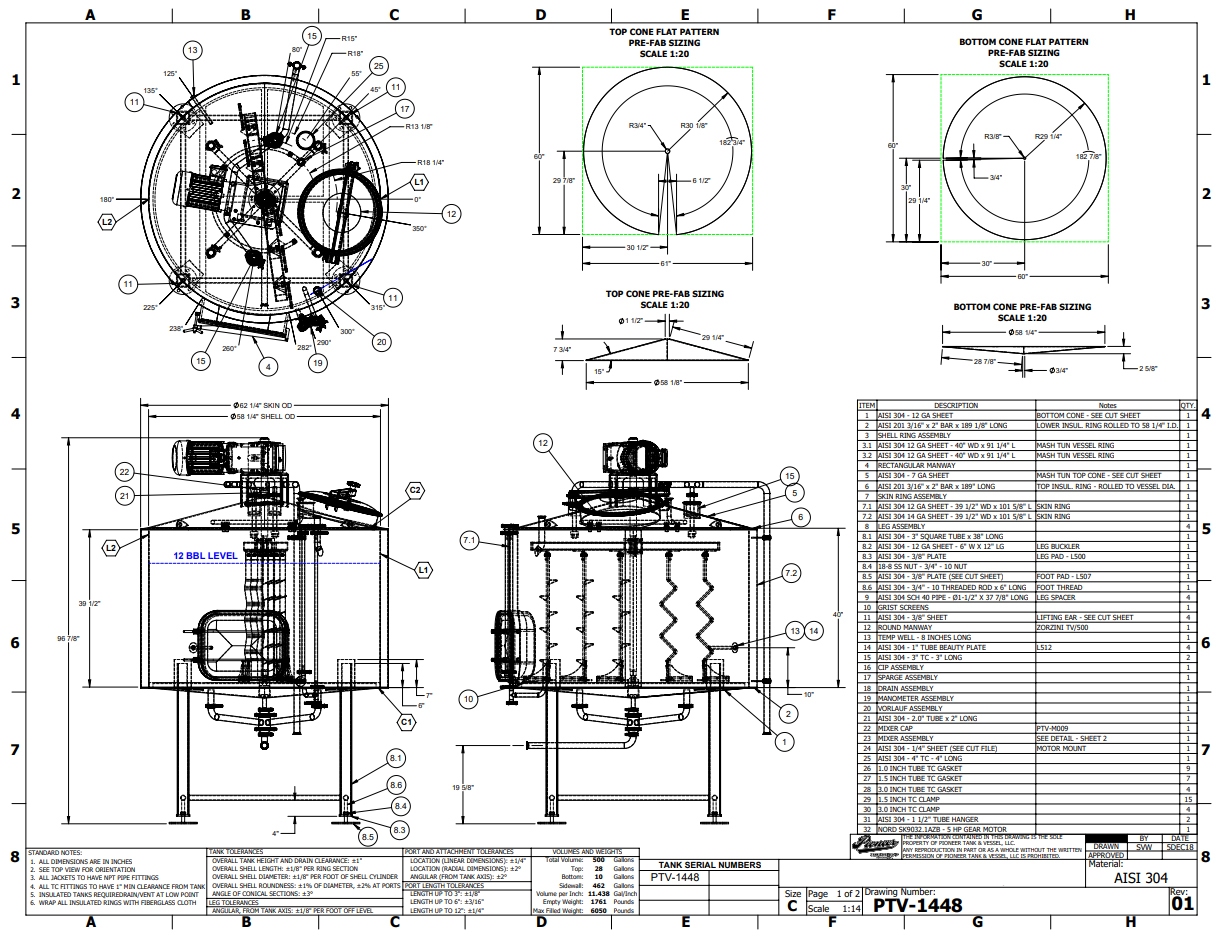

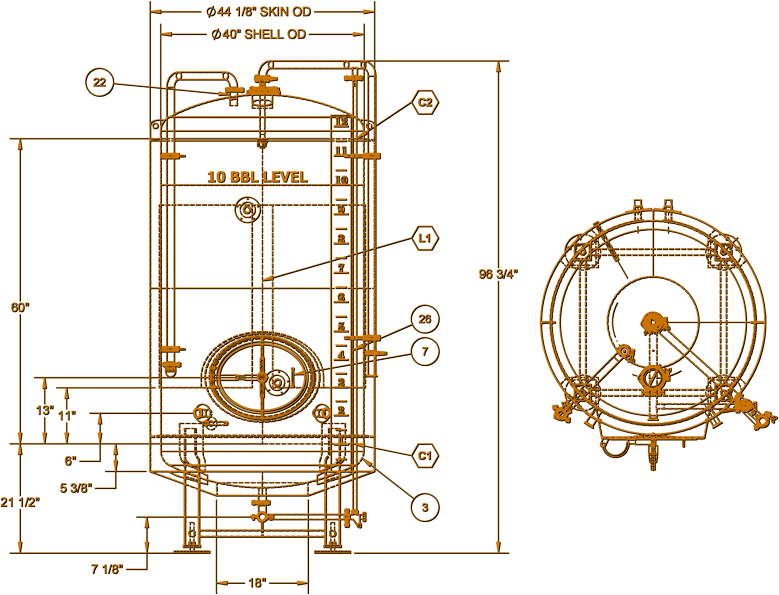

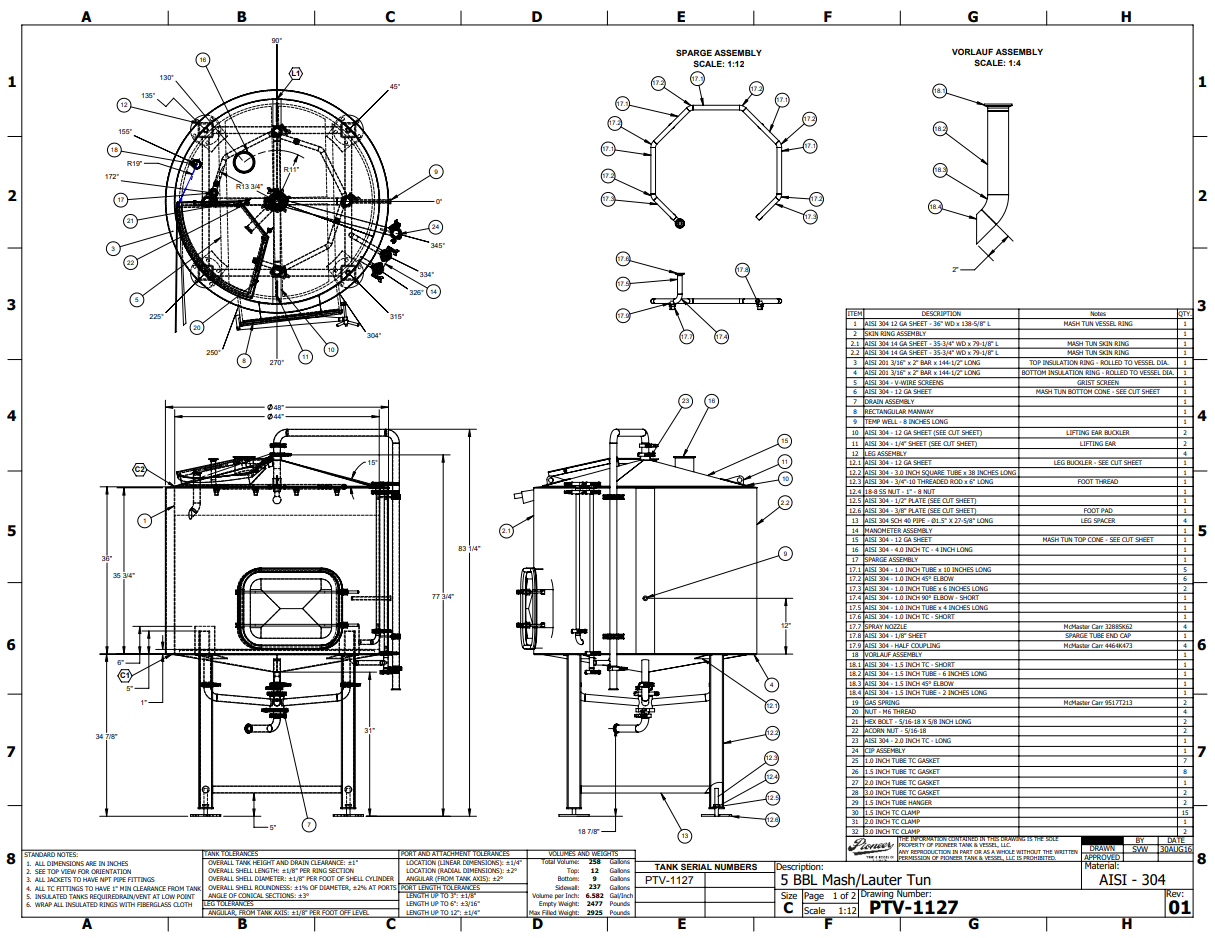

We use Solidworks CAD to model all our projects. Design, Engineering, and Drafting are done in the same department and usually by the same person. In the case of extraction equipment, there’s fluid dynamic restriction simulations, thermal conductivity and insulation calculations, along with material thickness calculations for pressure and vacuum vessels. Today’s CAD software gives us the ability to virtually build the project on a computer before we build it. We can see unintended interference from moving parts, or see hard piping conflicts before we are tasked with making complex piping decisions.

Our engineers need to have the experience and/or extensive knowledge of the fabrication process to be able to design a buildable product. There are times when a welding torch won’t fit into an area that needs to be welded. Or a vessel needs to be welded from the inside, but there’s no manway for the person doing the welding. Or the vessel is so small that a fabricator can’t get inside to polish the interior. Smaller tanks can be more difficult to build than large tanks. Our fabricators liken building small tanks to sewing doll clothes. The drafter has to take this all into consideration.