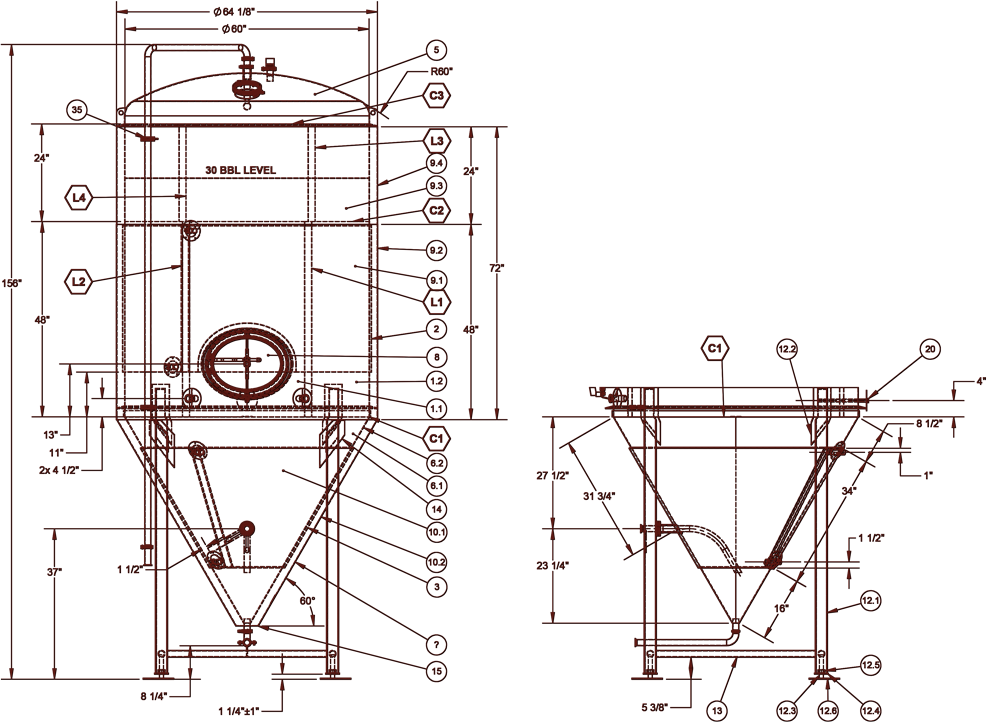

Concept & Design

The process of building something great starts with an idea. Many of our products evolve out of necessity for a product that doesn’t exist. The idea or concept gets hashed out over graph paper and turned into a sketch. Once the sketch matches the customer’s vision, our engineers translate that sketch into CAD (computer aided drafting) build prints for the customer to approve. There are usually some slight revisions, but once it’s signed off, the prints get handed off to the shop floor to build.

1

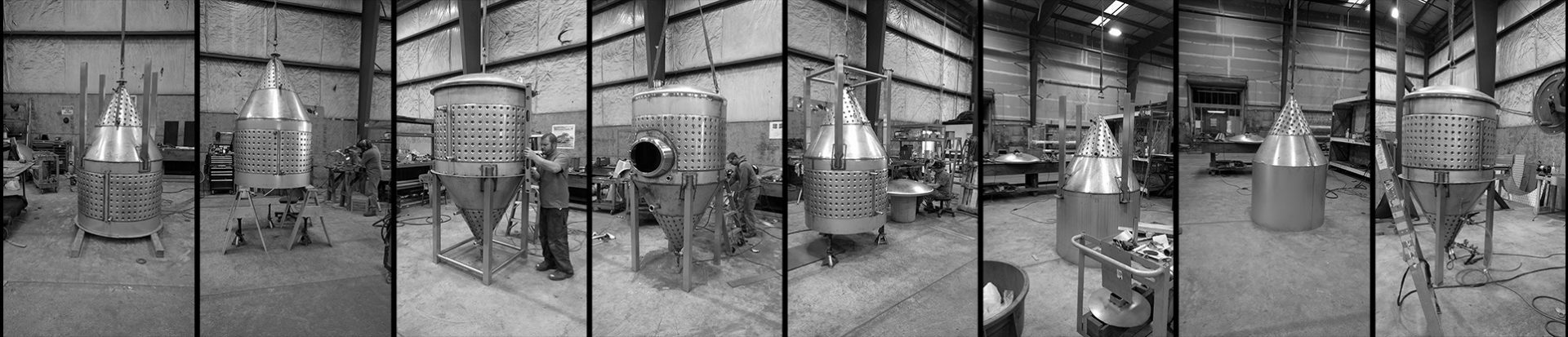

Build

We build almost everything from scratch. Stainless Steel sheet metal gets cut, formed, fit up, welded, and polished right here in our shop in Portland, Oregon. In a global economy where most products are built overseas, we’re proud to build by hand, and use local materials in our builds. We can be sure of quality by doing it ourselves without taking any shortcuts.

2

Test

Our traditional products are tested by hundreds of customers that use our products every day. We listen to their feedback and make refinements and innovations to always be moving forward to stay on the cutting edge of technology. Hemp and Cannabis extraction in an industrial landscape is a relatively new arena. We don’t have 800 years of experience to pull from like we do with Craft Beer Brewing equipment. The only way to be sure the equipment we build works is to test it, and run it hard until it breaks. Our sister company, InSupply Labs is next door to us and provides us with a unique position in the industry to be both a manufacturer of equipment and a full scale Hemp Extraction company. InSupply has a team of scientists and chemists, along with a full HPLC equipped analytical lab so we know exactly what needs to be improved.

3

Repeat

Much of the time our prototypes are successful the first time we commission them for extraction. Some of our more advanced systems take dozens of revisions to get to a level of perfection that we demand of our products. This is where having a full extraction facility next door gives us an extreme advantage in the market. This cycle from concept to testing is reduced to hours or days, and many times within a week we roll a prototype back over to the fabrication side for a revision.

4